Applications

From consulting to the selection of the right components, to the assembly and service of a complete system in the most diverse areas, you get everything from a single source.

Mill

With modernization and automation against the strength of the Swiss franc and price collapse - but how?

In order to constantly improve and to be able to offer high-quality CNC machines, Isel has made a revision of the proven machine series FlatCom M on 01.01.2018. See the details of the new machine concept here.

After the delivery of the CNC machine, we will assist you in the commissioning, the training, the specific programming solutions and the maintenance, as we have done for the application described in this article at the company Flexor.

The investments have already paid off within a year!

Flexor offers work for people with disabilities, from simple manual labour to monitoring complex machining processes. With around 45 individual workplaces, it is important to use devices and machines that are as efficient as possible, yet easy to operate.

After extensive consultation with teltec systems ag in Bremgarten, Flexor invested in three machines to replace older models and expand production capabilities. The Isel CNC Milling Machine Gantry Overhead M40 has a passage of up to 340 mm and a travel distance of up to 1200 x 1000 mm. Due to the high speed and travel speed, it is ideal for processing plastics.

Another advantage of the Isel CNC Overhead machines is the optimal use of space with minimum space requirements. Flexor manufactures plastic articles in large quantities up to one meter in size. Recently, teltec systems ag was able to supply two more Isel CNC gantry overhead machines (type M20). Ruedi Kirchhofer, Divisional Manager for Plastics Processing at Flexor, says: "The drives on the Isel CNC overhead machines from teltec are arranged at the top. This eliminates problems with chips that block the manufacturing process and other malfunctions. Next convinced us the price / performance ratio. The commissioning of all three machines and the instruction was exemplary.

High-performance CNC machines and CNC milling machines: precision work by isel

Isel's CNC machines and CNC milling machines are basic machines for production and combine state-of-the-art CNC control with extreme precision and flexible technology. They are used as CNC milling machine, boring machine, engraving machine, dosing machine or also as special machine as well as machining centres and are used in all areas of the metal industry, wood and plastics industry, where high demands on traversing measuring and repeat accuracy have to be met.

Measuring Technology

Due to the modularly oriented products including open interfaces of the used controllers and software, we were able to build a very interesting price system that fully met the customer's requirements.

The control and the attached linear measuring system give us the exact position of an axis. However, in order to verify the exact position in the room (interaction of all axes), the measurement by means of a laser tracker system is required.

The 3-axis Ganty measuring system with 3 x 1 m travel was set up on a stable measuring plate. For the acceptance of the system, the customer made a detailed acceptance test in which 125 points in the room were accurately measured by means of a laser tracker system. Thus, a 100% reliable target / actual comparison could be produced and the requirements according to the test could be agreed.

In order to verify the repeat accuracy, 9 measurement points were selected, which had to be approached 10 times.

3-D printer

With the help of competent isel staff I was able to find a solution for my product. The ball screw spindles are the heart of my design and the reliable operation and repeatability are absolutely given. With a large selection of accessories and mounting options for the screw-nut and bearing I was able to complete the designs for my application within a very short time. – Video of the application

Laser Marking Medical Technology

https://www.fobalaser.com/industry-solutions/medical-technology/

Laser Marking Machine Construction

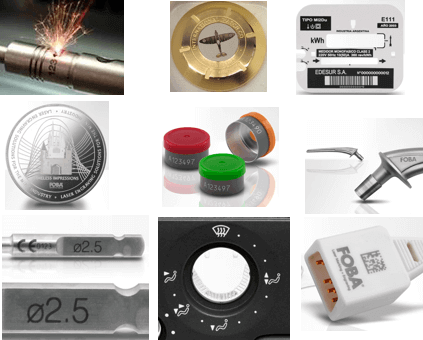

Laser Marking Applications

Economic alternative / Try us

Benefit from our many years of experience in laser marking, our partnerships with technologically leading laser manufacturers and our innovative process approaches. So we can offer you a technologically high-quality, economical and extremely flexible laser marking according to your requirements in our house.

We offer an extremely flexible laser marking according to your requirements in our house. We are also happy to produce samples for later series. The delivery of the parts takes place in agreement with you either by forwarding agency, parcel service or with the own vehicle.

Product examples

Workpieces and materials

We laser almost all shapes and parts:

- Stainless Steel

- Stole

- Titanium

- Aluminium

- Plastics (as far as appropriate)

- Films

- Hard Metal

Possibilities

Labeling content is virtually limitless - ranging from manufacturing and shelf life data, as well as lot and serial numbers, graphics, images and logos to 2D matrix and barcodes as well as individual content. Thanks to our integrated intelligent marking positioning system, we can guarantee consistent and highest quality machining.

Required information

In addition to the material delivery, we need your labelling information, which you can supply us as vector data (* dxf), or we will create the necessary graphics and fonts for you based on your information.

Proper and consistent identification of your property will prevent theft, misuse and tampering

Sheet Metal Processing

Ultra short pulse laser in the fine sheet metal technology

SMM Report November 2017 Report Businesslink

n order to achieve exceptionally high marking contrasts and to process almost all materials, HAKAMA decided to use a picosecond laser. The great advantages of markings with this diode-pumped, mode-locked solid-state laser are the ultra-short pulse durations of the energy beam. These allow non-linear multiphoton absorption processes, which makes material processing largely independent of the laser wavelength. In other words, the unique quality of markings on a variety of materials is largely dependent on this extremely short pulse duration, in which there is almost no temperature change on the surface.

This means that almost all materials can be processed, even those that are transparent at the laser wavelength. Another advantage of ultrashort laser pulse durations is the "cold ablation" of the material, which is not based on the generation of heat, such as nanosecond lasers. The generated nanostructure on the surface serves as a light trap, whereby a significantly increased contrast and also a higher black level are achieved. Further, there is no reflective angle (shine) which causes the mark to appear in varying contrast or colour as the viewing angle changes. The marking is therefore always dull black. Another advantage of this type of label is the hydrophobic nature of the label. Liquids are generally rejected, resulting in significantly higher corrosion resistance even in chemical cleaning and sterilization processes.

For this reason, PHOTON ENERGY's CEPHEUS picosecond laser is used for all laser processing processes in which damage from melting, deformation or discoloration due to heat input is undesirable and a maximum optical stability of the marking is required.

The pulse energies of up to 300 microjoules provide less material removal per laser pulse than a nanosecond laser, thereby additionally increasing the precision of material processing, such as in very small and precise drilling applications. In general, it is used wherever precision requirements of nanosecond lasers can no longer be met.

In summary, it can be said that the picosecond laser markers have the following advantages over longer pulsing lasers, such as nanosecond fibre laser sources or Nd: YAG lasers.

- Faster marking due to higher pulse peak powers

- More uniform marking due to surface structure change (light trap) instead of tempering by means of energy input by temperature

- Consistent contrast (light trap) at changing light incidence and viewing angle

- Higher resistance of the marking during abrasive, chemical and radiation exposure

- Almost all materials can be marked, including foils, all metals, all federal metals, all precious metals, all thermoplastics, all thermosets, most elastomers, glass, diamond, lacquer coatings, etc.

- Surface of the label has hydrophobic (water-repellent) properties

The laser marking machine TelspezX2Y1Z05 with the picosecond laser from the company PHOTON ENERGY, built by the company teltec systems ag in Bremgarten, Germany, is an open laser marking system specially manufactured according to the wishes of the company HAKAMA. Due to the travel range of the laser head of 2000 x 1000 x 800 mm, even large parts can be processed fully automatically.

Testers

Liquid micro-flow rates

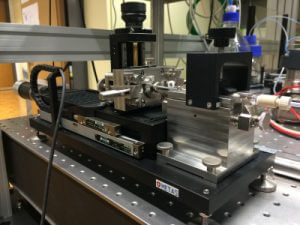

METAS has developed a method for the calibration of "liquid micro-flow rates". Micro and Nano flow calibration is e.g. essential for various applications in the field of drug delivery. With the help of high-precision OWIS linear stages and specially developed syringes, METAS has developed a standard for verification for flow rates from 1 ml / min to 100 nl / min with an uncertainty of 0.1% to 0.6%.

METAS has developed a method for the calibration of "liquid micro-flow rates". Micro and Nano flow calibration is e.g. essential for various applications in the field of drug delivery. With the help of high-precision OWIS linear stages and specially developed syringes, METAS has developed a standard for verification for flow rates from 1 ml / min to 100 nl / min with an uncertainty of 0.1% to 0.6%.

This system has been realized with a high precision OES linear stage LIMES 80-130-Hi00 to meet the high demands on accuracy and finest steps. The features of this OWIS table are:

High precision linear stage with 135 mm travel - with endcoder and Hall-effect limit switches - with bellows - backlash-free ball screw with 1 mm pitch - preloaded recirculating ball bearing guideways - servomotor (2000 pulses / rev) - motor current max. 2.0 A - motor voltage max. 36 V - repeat error (bidirectional) <2 μm - load capacity max. 150 N - actuating force max. 60 N - speed max. 25 mm / s (control-dependent) - connection: 26-pol. HD plug (male)

The table is equipped with a DC servo motor with gear reduction ratio 5: 1 for a speed of 0.1 - 10 mm / s, as well as with a linear measuring system with the accuracy class +/- 3 μm / m and a resolution of 0.1 μm